|

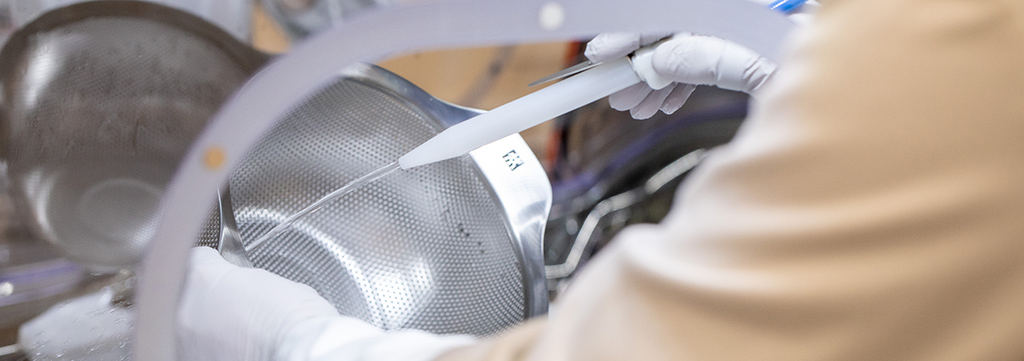

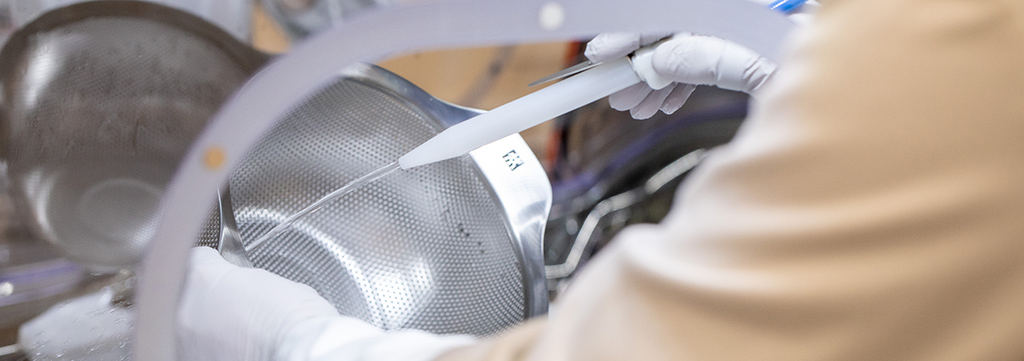

Technical cleanliness is carried out to check for contamination by fine particles (metallic, non-metallic, fibres, etc.) that adhere to components and parts, thereby affecting the quality, safety and durability of products.

These impurities can cause malfunctions, leading to premature failure of the product assembly or at least less efficient functioning.

The components are subject to a permitted presence of impurities:

- the mass of impurities per product or surface (gravimetric requirement),

- particle size distribution,

- maximum particle size.

Technical cleanliness analysis is performed on:

- plastic pieces,

- metal pieces,

- printed circuit boards.

Technical cleanliness analyses are carried out according to the following standards and specific requirements:

- ISO 16232:2018,

- VDA 19, part 1:2015,

- car manufacturers (e.g. PV 3347),

- the client’s requirements.

At LOTRIČ Certification we offer:

- help you understand the requirements of the standards,

- technical cleanliness testing services on products,

- monitoring cleanliness in production.

| Completion time: 5-10 working days from receiving the samples. |

|