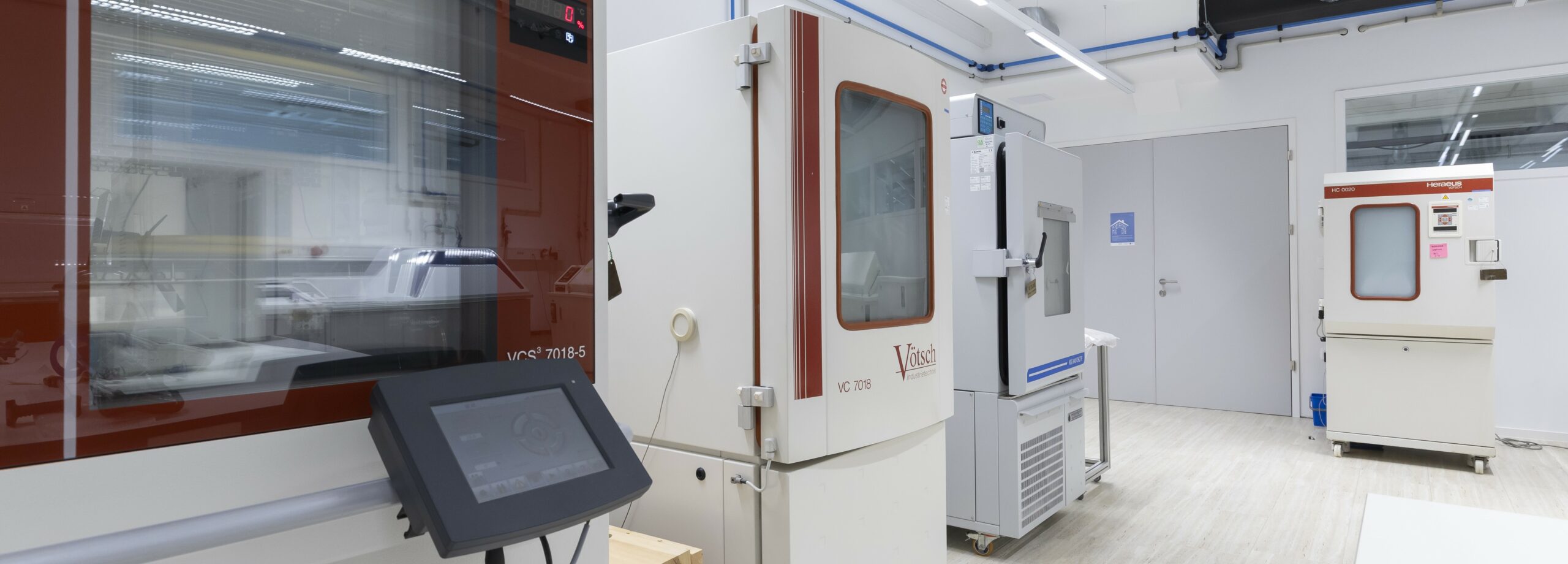

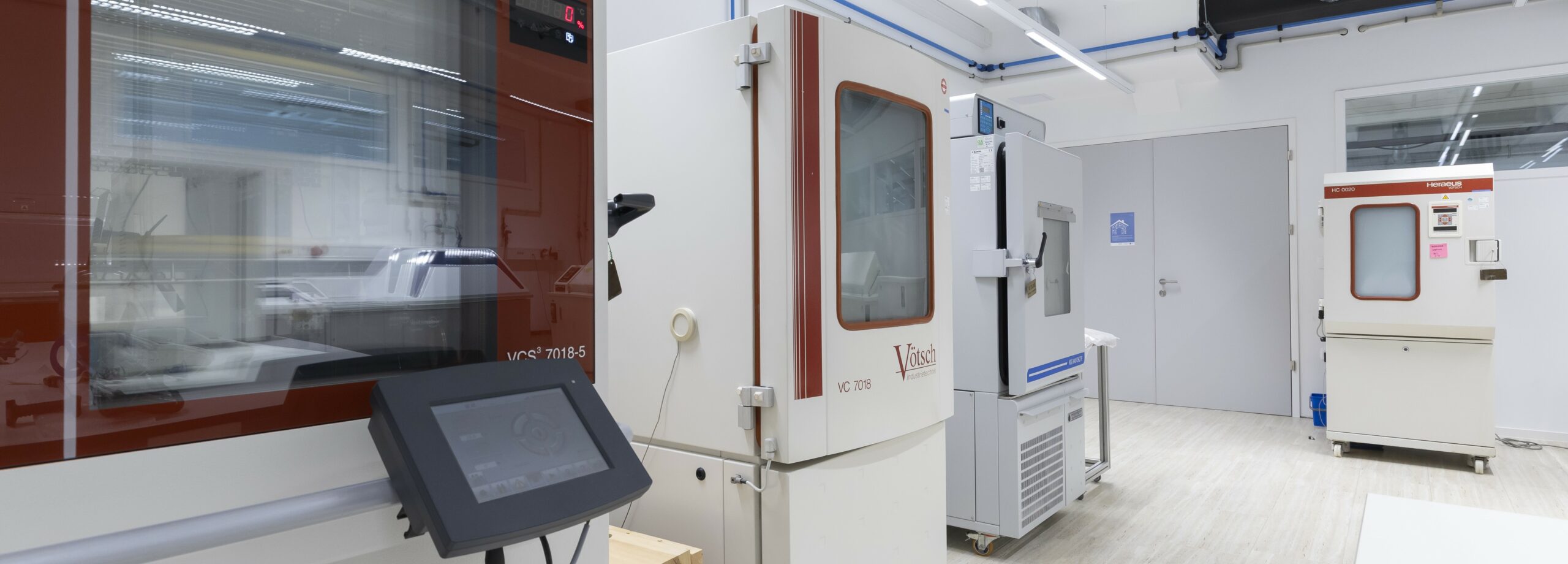

Exposure in Specialized Chambers

In dedicated chambers, we perform:

- Thermal shock test (-60 °C to 200 °C),

- Test in condensation-water atmosphere – ISO 6270-2 or BMW AA-0213,

- Test in condensation-water atmosphere in presence of sulphur dioxide (SO₂) – Kesternich test – ISO 22479.

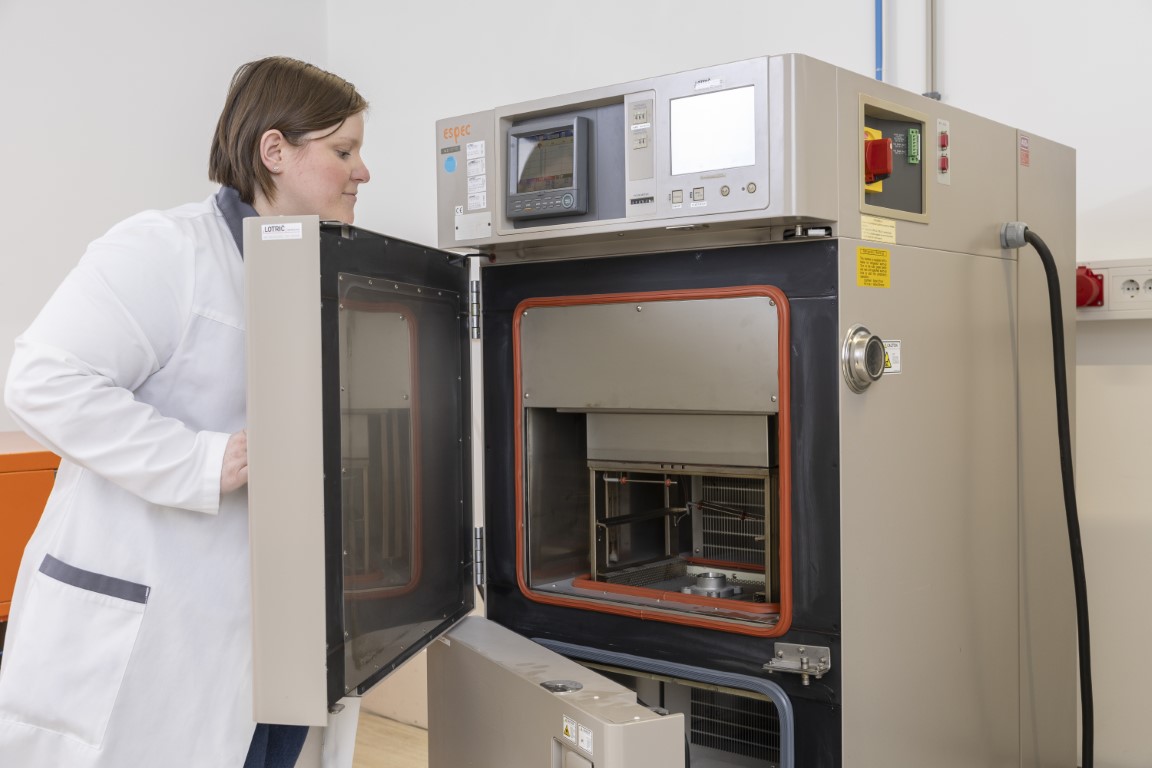

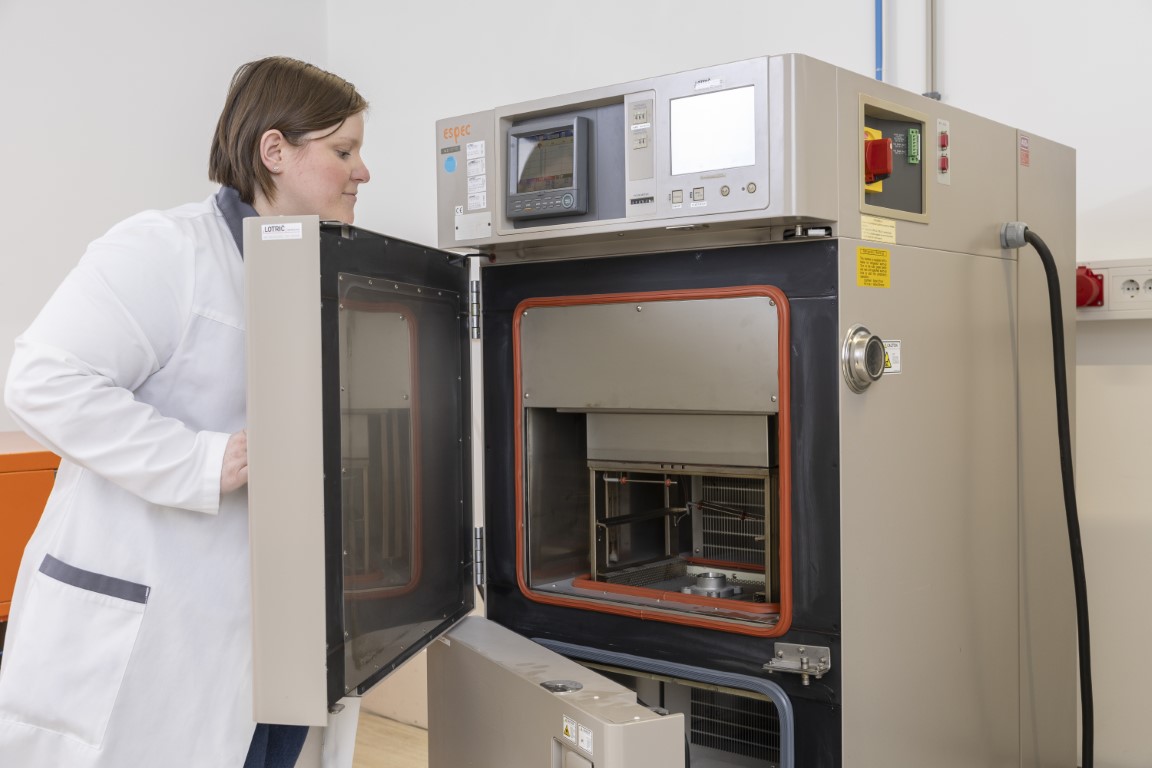

Thermal shock chamber consists of two separate compartments, one for low and one for high temperatures. A lift transfers the specimen between these levels in approximately three seconds. This cyclic test is repeated multiple times to assess material resistance to rapid temperature changes, such as expansion, cracking, and peeling.

When testing coated test specimens in condensation-water test atmospheres, samples are exposed to 40 °C and 100 % relative humidity. There are three condensation test methods: CH, AHT and AT. The CH method involves constant condensation, while AHT and AT methods feature cyclic variations in humidity and temperature.

|